Introduction

There are three design considerations which need to be given extra attention during the planning stage of building an energy efficient home or if planning a major energy efficient renovation of an existing home.

The housing site and prevailing winds or lack of, need to be considered. Natural ventilation, harsh winter winds or natural protection (trees, berms, buildings) can all effect long term comfort and home energy performance. Solar access combined with the house shape and placement on the building site also has a great effect on overall performance and comfort. The floor plan and interior layout in relation to your particular current and future family's wants and needs, is an equally important design consideration.

This section details these important design considerations as a part of the 'house as a system' planning approach. Although energy efficient housing can be built with any style or type of housing, on any site or compass direction - winds, natural protection and solar energy are free and produce no pollutants. Changes made at the planning stage regarding these design considerations have very little cost but can produce significant lifetime improvements in home energy usage, comfort and usability.

Initial Planning

Site Planning

An ideal site for designing and building an energy efficient home, would have full solar access and protection from the harsh elements of nature. These type of building sites however, are often found only in acreage or rural settings. Unfortunately most urban building sites and housing developments are laid out for ease of development and access, looks and location, or convenience to main service roads.

Fortunately, energy efficient housing works on any site or lot, with any style or type of housing, on any compass orientation. Although your lot may not have any solar access you can still build an energy efficient home.

When planning your building site you must know the prevailing winds in your area to take advantage of them. Shelter from the winter winds and cross ventilation from the summer winds can be incorporated into the planning stage. Housing on urban lots must consider the effects on wind flows and daylight, that the adjoining lot development and house placement will have. Information regarding wind direction and speed is available from most local weather offices.

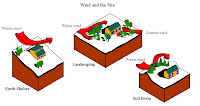

If the immediate environment around the home is well protected, entries will be more comfortable to use, outdoor play spaces will be usable on sunny winter days and outdoor eating areas will remain pleasant from spring until fall. As the illustrations show, vegetation and soil berms can be used to control winds around a site.

Site Planning

An energy efficient home is not necessarily a solar home, but solar energy can, and often is used, to further lower energy consumption. This applies only if the site conditions allow good solar access (a southern exposure). In a cold climate, solar energy has the potential to supply 20 to 60 per cent or more of the heating requirement of a home.

To maximize solar potential the home must be the proper shape and have unobstructed solar access. The optimum building shape is one which gains the maximum solar energy in the winter yet has the least exposed exterior surface area. The sphere has the least surface area in terms of volume enclosed and is the most efficient, but is not a very practical building shape. A square offers a more practical building shape, but southern surface area can be limited. The rectangular shape offers the best compromise for solar gain since it exposes a larger area to the sun while keeping the total surface area to a practical minimum.

An elongated rectangular shape along an east-west axis exposes the longer south side to maximum heat gain in the winter.

Research has shown that a long side to short side ration of 1.5 to 1.0 is optimum in a cold climate. The low winter sun shines almost directly on the vertical south side. Windows will then intercept the maximum amount of solar radiation available during the winter months.

Solar Planning

Solar Access

No obstacles should be in the way of the low angle rays of winter sun. This solar access must be clear from about 9.00 a.m to 3.00 p.m when over 90% of the winter solar radiation occurs. If the sun is blocked for even one hour, up to 20% of this energy will not be available. Remember, some deciduous trees, even without their leaves, can block up to 50% of the sun.

The Long side can face as much as 30 degrees east or west of true south and still receive over 90% of the available solar energy. This means quite a degree of flexibility when siting the home. Orienting most south-facing windows to the east of true south means early warming of rooms in the winter. Orienting the windows more to the west of true south allows more afternoon warming although this will require additional shading during the summer months to avoid possible overheating.

Summer Shading

During the summer, the south side receives less solar radiation than the roof because the sun is higher above the horizon. Overhangs can be designed to block the sun and control overheating by shading windows in the summer.

The length of overhang required is calculated by dividing the distance from the underside of the overhang to the sill of the window by 1.7. This length of overhang would then shade the window from late May to early August for most central Canadian climate latitudes. When the sun is lower in the sky the window becomes less shaded so all available solar energy enters during the heaviest heating season - November to March. West facing windows are subject to overheating all year long because the setting sun is low no matter what the season and will require extra shading or Low-E window units.

Check with your local weather office or service for winter sun angles for your area.

Passive Solar

Passive solar energy systems require no energy to operate and are an intrinsic part of the home design. Passive systems add little additional cost, operate with almost no supervision and require little or no maintenance. The basic elements of all passive systems are south-facing windows and internal thermal mass. Solar heating is simply sunlight entering the house that is absorbed and converted into heat energy which is later released inside the house as it cools. Any house with south facing windows can be a solar home.

An energy efficient passive solar home works through proper design which makes good use of the sun's energy for heating and lighting. while providing the opportunity for sunny rooms, attached sunrooms and solariums. With reasonable solar access, almost any plan or style of house can incorporate passive solar features. An energy efficient home is not necessarily a solar home, but solar energy is very effective at lowering energy consumption and associated costs.

Attached sunspaces and solariums have become more popular as a way to lengthen our growing season and enjoy a little more time in the sun. With a great variety of styles available, sunspaces fall into two broad categories of freestanding and lean-to types. Solariums are usually incorporated into the internal dimensions of a home.

Sunspaces and solariums work by admitting solar heat (sunlight) which is absorbed by the materials inside it - concrete or tile floors, masonry walls in sunspaces attached to homes, storage containers of water, wooden plant benches full of dirt - the greater the mass, the more heat the space will be able to absorb.

Direct Gain

The simplest passive solar heating design is the 'Direct Gain' approach. This means that the space within the house or sunroom is heated by direct sunlight. If the space is used as a solar collector, then it must also contain a method of absorbing and storing enough daytime heat to be useful at night. The house itself becomes a sort of live-in solar collector with heat storage and distribution built right in. Direct gain systems work continually collecting solar energy from either direct sunlight or diffused light through clouds or haze.

With the direct gain approach, south facing glass is exposed to the maximum amount of solar energy in winter and the minimum amount of solar gain in summer. Since a portion of this heat can be captured and stored for use at night, the walls and/or floors need to be constructed of materials capable of storing additional heat.

This interior heat storage helps prevent large fluctuations of indoor temperatures during the day while storing the extra heat for later use. The most common mass used is composed of masonry materials such as brick, floor tile, masonry, stone or concrete, although water storage can be used as well. Phase change materials which can store tremendous amounts of heat energy are being developed but are currently not widely available and are costly.

Most homes contain enough thermal mass in walls, floors and furniture to absorb the energy coming in through south-glazing sized at a maximum of 8 to 10% of the total floor area.

In northern latitudes, less glass area is often used to reduce excessive winter heat loss. Energy efficient homes which have very low heat losses will also require less south glass area, unless the internal thermal mass is increased to avoid overheating. Problems with direct gain passive solar homes can include glare and sunlight-faded fabrics.

If the window area increases (10 to 15% or more) relative to floor area, then special glazings and additional thermal mass will be required. This mass can be in the form of a concrete floor, heavy floor tiles, masonry planters, masonry or brick feature walls, a stone or concrete fireplace, or some type of water storage container. As a general rule, for each one square foot (1m2) of south-facing glass in a space over the 10% maximum, one needs five square feet (5m²) of masonry four inches thick (100mm) or the equivalent in increased thermal mass (a ratio of 1:5). Because mass absorbs and releases heat slowly, expect wide temperature swings in the order of 10°F (5°C) in direct gain spaces with larger window areas.

Where large window areas are involved, there are two methods for reducing nighttime heat loss, which in cold climates can be very high. The first is the use of current window technology which combines Low-E coated glazings, insulating spacers and insulating gases between panes to provide R values above 5 (RSI-0.87). Specialty Low-E coated glazings and window films can also be used to help control excessive heat gain and ultraviolet. The other is the use of window insulation at night to help reduce heat loss.

Studies in Canada and the northern U.S. have shown that a conservative passive solar approach is more economical in both capital cost and performance. This approach starts by super-insulating and air sealing the building to reduce the heat load as much as possible. A small amount of well insulated, south facing glass allows direct solar heat gain without incurring radical temperature swings within the building. Instead of adding extra tons of rock in or under the structure, existing mass in the form of flooring (tiles) and additional gypsum wallboard and (perhaps some strategically placed masonry), is utilized. This approach adds very little cost as only the windows need to be upgraded. The collection, storage and distribution of heat within a purely passive home is done without mechanical devices using convection and radiation.

Indirect Gain

Indirect Gain is when sunlight strikes a thermal mass which is located between the sun and the space to be heated. The sunlight absorbed by the mass is converted to thermal energy and then transferred into the living space. The most common type of indirect gain system is the thermal storage wall.

Trombe Walls are the most commonly known form of indirect gain. The thermal mass wall should be located 4 inches or more directly behind the glass. These walls are usually made of masonry. Alternatives include water walls, roof ponds or attached greenhouses.

Indirect gain systems can work well with energy efficient homes because of the ability it provides for better control of passive solar heating. In this type of system, the sunlight strikes a thermal mass inside of or in between it and the interior space to be heated. With this system, large areas of glass can be used. The design rule of thumb here is one square foot or metre of south-facing window is required for each square foot or metre of floor area you wish to heat. Insulation of the glass at night is a must to prevent heat loss from the mass to the outside. The mass must be 12 to 18 inches thick (300 to 450 mm ) if masonry or 8 inch thick (200 mm) if water. This type of passive solar collection system works well if there is good solar access and a view you don't mind blocking with mass walls. Thermosiphoning slots at the top and bottom will slightly increase the energy absorbed into the space - but the slots must be blocked at night to prevent the reverse effect (heat being removed from the space).

Solar Spaces

Sunspaces and Solariums

Attached sunspaces or solariums are often combined direct and indirect gain spaces. They are directly heated but can provide an indirect means of heating the house. These types of spaces usually have lots of glass area and can be subject to severe overheating or heat loss, especially when both the roof and walls are glazed. It is important that the spaces are well designed with provisions for spring, summer and fall ventilation to control heat build-up. One drawback with passive solar sunspaces and greenhouses is that summer overheating can be severe when no one is home to operate manual shading or ventilating devices.

A simple attached lean-to style sunspace can be a useful heat gathering space - it can stand large temperature swings and can be closed off and not heated in the middle of winter. If designed properly, a sunspace can be an enjoyable, convenient outdoor insect-free space (with large screened openings in summer). It can be used for bedding plants, and to extend the fall tomato harvest but, unless lots of energy is pumped in over the winter months, It can be more economical to leave the sunspace dormant from November to February.

Most sunspaces however are used year round and often do double duty as small family plant rooms and greenhouses. Sunspaces are most often integrated with the house and heated with the main heating system. A passive solar sunspace can help to reduce the increased heating cost associated with a year round sunspace located in a cold climate.

Passive solar heating is free and produces no pollutants.

To help heat the home, mass storage and some method of transferring the heat to the living space is required. This can be a mass wall between the two areas, water storage containers, forced-air distribution system or a rock storage/air distribution system. Some storage bed systems can lead to complicated damper, fan and thermostatic control functions which is not in keeping with the concept of passive collection.

Greenhouses

A greenhouse is totally different. Plants cannot tolerate large temperature swings, thrive best in high humidity, and require heat in winter and ventilation in summer to survive. The large glass areas need winter insulation and summer shading to create a reasonable atmosphere for growing things. Condensation is often a problem created by the high level of humidity associated with plants. A working, active, attached greenhouse will actually increase the heating costs of your home because it is another room to heat with a high heat loss rate in the winter. Insects can be a problem as well and pesticides should not be used in an airtight structure. A working greenhouse would have to remain isolated to keep pesticide residues out of any attached living space. This would severely limit the greenhouse as an effective passive heat source for the home.

Interior Planning

Plan Layout and Zoning

As pointed out, a rectangular house shape is most efficient in terms of solar energy gain and minimum surface area heat loss. The challenge then becomes one of arranging all the spaces your family needs into that rectangular volume.

First list all the areas you require. These are the basic requirements such as a kitchen, bedrooms and bathrooms. Just as important are the living spaces, special work areas, storage, mechanical rooms, entries, etc. Beside each space you list, note the area required. Totalling the areas and adding 25 to 30% for circulation, storage space and wall thickness will give you approximate total home area. It may be hard to visualize the size of the spaces you need. Measure the rooms you live in now for ideas on size. Utilize scale furniture in planning each room so that nothing is left out of your plan - you should involve planning for future furniture purchases also. To eliminate future space problems, it is important that sound decisions are made with regard to space. The planning stage is the best time to make them.

As noted in initial planning a rectangular shape offers the best compromise of house volume versus exposed exterior surface area. There are many configurations for a solar-oriented home. A bungalow or bi-level with a fully developed lower level, a two-storey home, or a one and one-half storey house will, as illustrated, result in the basic rectangular shape.

The next task is to arrange the spaces required into the desired house shape. Draw each space to approximate scale size as a bubble, rough square or rectangle on a piece of paper. Cut them out and arrange them in different ways to help you visualize a final layout. At this point consider the views from each space, the natural light and ventilation requirements, and the room-to-room relationships.

Analyze each room individually with regard to windows and doors, then how it will relate to other rooms in the plan. Certain rooms, such as living or family rooms, require lots of natural light, can be good passively heated spaces and will be used by all family members - these rooms are termed the living zone. Other rooms, such as the kitchen, utility and bathroom areas, require plumbing, more artificial light, lots of storage facilities and are referred to as the working zone. Quiet, private bedroom areas are called the sleeping zone. An important aspect of successful planning is maintaining separate zones - keeping noisy and quiet areas apart.

Consider solar energy when laying out the rooms for an energy-efficient home. The graphic illustrates a potential bungalow layout which places the working zone (requiring few windows) on the north side, the sleeping zone on the east side (where early morning sun is appreciated) and the living zone on the south side (where the sun can warm the spaces during the day).

If the lower level is to be developed, 'vertical' zoning is also important. The potential bilevel layout plan shows how the three individual zones are kept separate vertically (one above the other) as well as horizontally. Isolating bedroom and living areas above one another keeps quiet areas well separated from the lived-in zones.

In any home plan compromises usually have to be made. Some areas requiring windows may be on the north, bedrooms may face west because there isn't room for all of them on the east, or vertical zoning rules may be broken - as often is the case in a two-storey home.

The three levels shown in the illustration, have been arranged for solar access to all living and sleeping areas. The utility room, bathrooms, entries, and the garage have been placed as a buffer on the north side.